MCP(Manufacturing Collaboration Protocol)是面向制造业的开放式协作协议,其核心价值在于实现跨系统、跨设备的标准化交互。以下是深度集成MCP协议的技术方案:

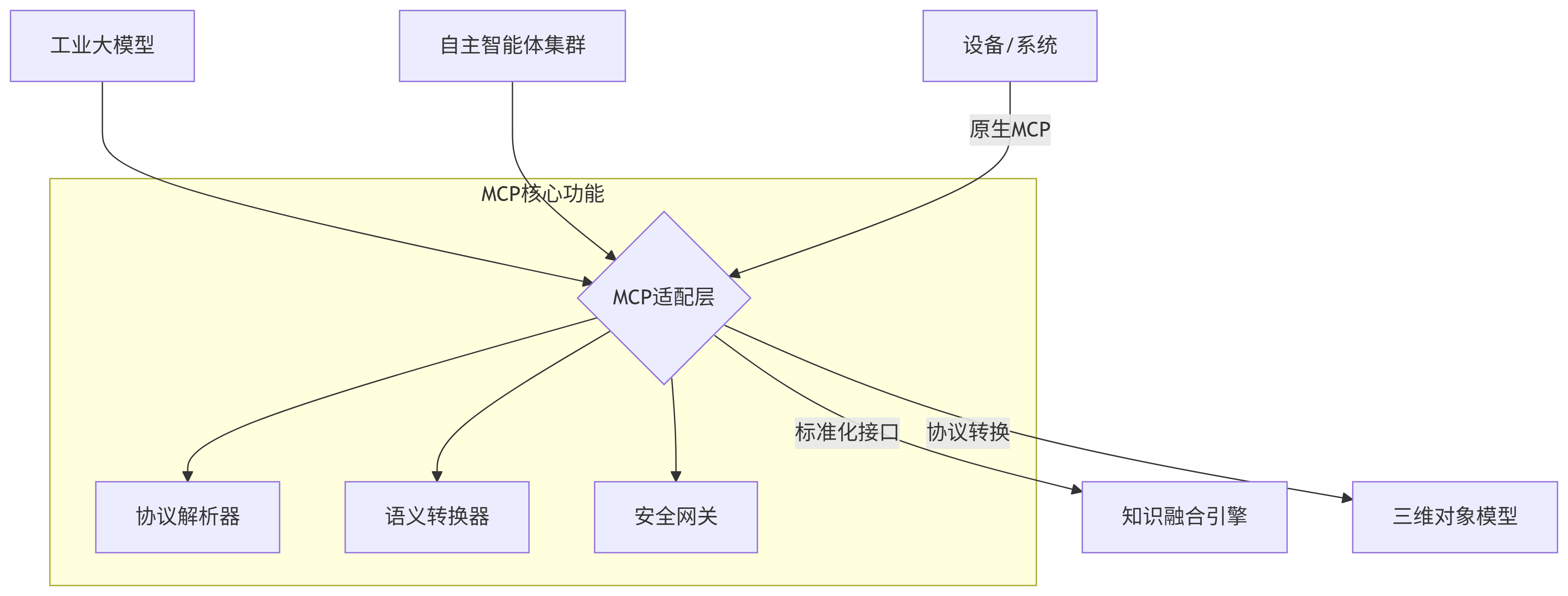

🌐 协议适配层架构

🔧 MCP适配层关键技术实现

1. 协议解析引擎

python

class MCPAdapter:

def __init__(self):

self.parser = MCPParser()

self.translator = SemanticTranslator()

self.security = ProtocolSecurity()

def handle_message(self, raw_data):

# MCP协议解析

mcp_msg = self.parser.decode(raw_data)

# 安全验证

if not self.security.validate(mcp_msg):

raise SecurityViolation("Invalid MCP signature")

# 语义转换

std_msg = self.translator.to_standard(mcp_msg)

# 路由分发

if mcp_msg.msg_type == "EQUIPMENT_STATUS":

return self._handle_equipment(std_msg)

elif mcp_msg.msg_type == "PRODUCTION_ORDER":

return self._handle_production(std_msg)

def _handle_equipment(self, msg):

# 转换设备数据为三维模型输入

model_input = {

"device_id": msg.device_id,

"params": self._extract_parameters(msg),

"timestamp": msg.timestamp

}

return self.object_model.update(model_input)

def _handle_production(self, msg):

# 转换生产指令为智能体任务

task = ProductionTask(

order_id=msg.order_id,

product_spec=msg.specification,

deadline=msg.deadline

)

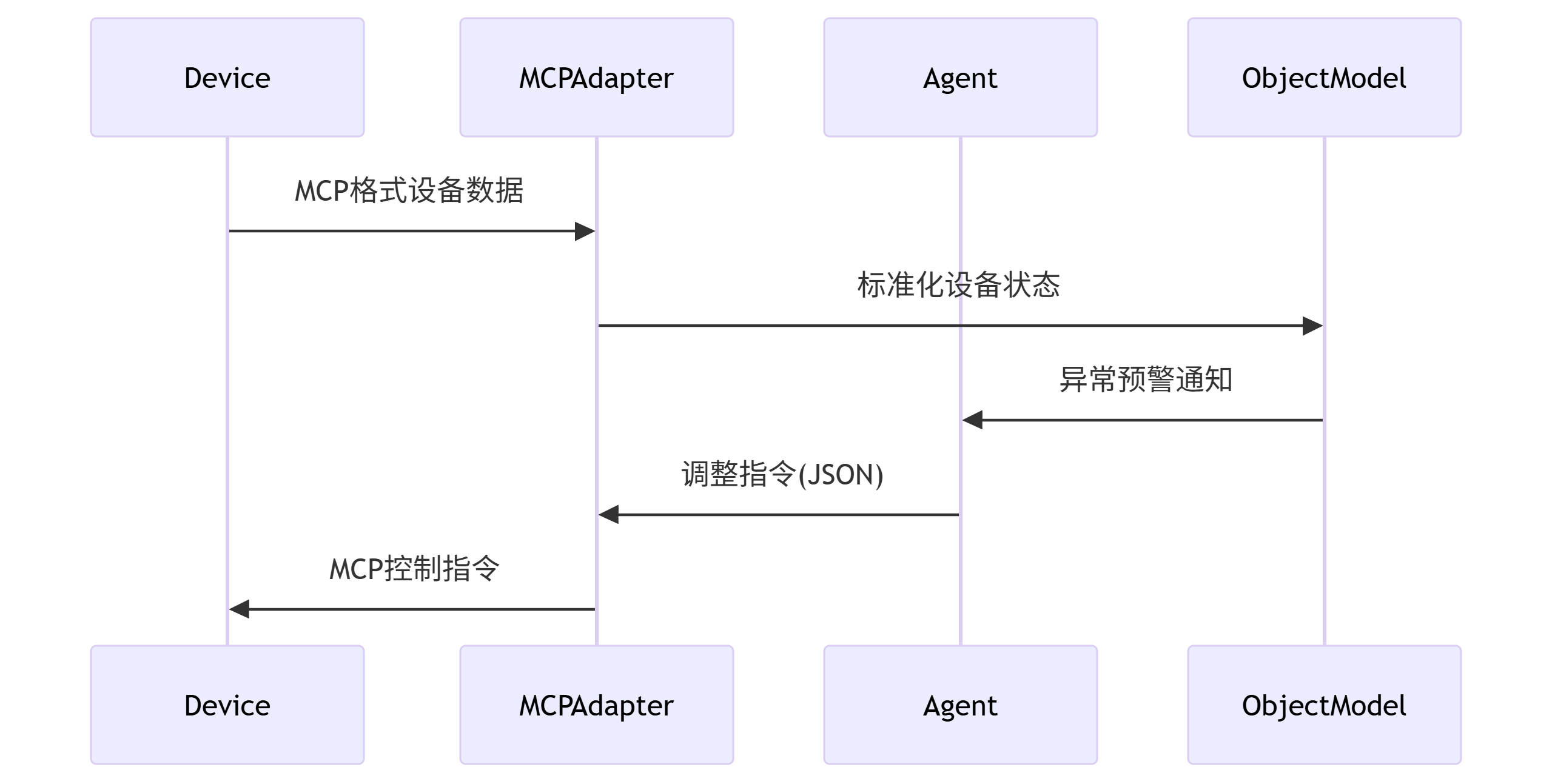

return self.agent_coordinator.dispatch(task)2. MCP-智能体双向通信机制

3. 协议转换矩阵

| MCP协议元素 | 系统内部表示 | 转换规则 |

|---|---|---|

| EQUIPMENT_STATE | DeviceStatus | 状态码映射表转换 |

| PROD_ORDER | ProductionTask | BOM结构转换 |

| QUALITY_DATA | QualityMetric | 测量单位标准化 |

| MAINT_ALERT | MaintenanceEvent | 优先级映射 |

🚀 MCP增强的智能体协同流程

python

class MCPEnabledAgent(QualityAgent):

def __init__(self, mcp_adapter):

super().__init__()

self.mcp = mcp_adapter

def detect_defects(self, inspection_data):

# 本地AI分析

local_result = super().detect_defects(inspection_data)

# 通过MCP获取关联设备状态

equipment_status = self.mcp.get_equipment_status(

machine_id=inspection_data.machine_id

)

# 综合判断

if local_result.confidence < 0.9:

# 发起MCP跨系统质量验证

cross_system_check = self.mcp.request_quality_verification(

sample_id=inspection_data.sample_id,

test_type="XRAY_ANALYSIS"

)

return self.fuse_results(local_result, cross_system_check)

return local_result

def recommend_improvements(self, defect_data):

# 生成优化建议

improvement_plan = super().recommend_improvements(defect_data)

# 转换为MCP指令

mcp_commands = []

for action in improvement_plan.actions:

mcp_commands.append(

self.mcp.create_command(

target=action.target_device,

command_type="PARAM_ADJUST",

params=action.new_parameters

)

)

# 批量执行

return self.mcp.batch_execute(mcp_commands)🛡️ MCP安全增强机制

python

class MCPSecurity:

def __init__(self):

self.validator = DigitalSignatureValidator()

self.audit_log = BlockchainAuditLogger()

self.threat_detector = AnomalyDetector()

def validate(self, mcp_message):

# 1. 数字签名验证

if not self.validator.verify_signature(mcp_message):

return False

# 2. 异常行为检测

if self.threat_detector.detect_anomaly(mcp_message):

self.quarantine_message(mcp_message)

return False

# 3. 权限检查

if not self._check_permissions(mcp_message):

return False

# 4. 审计日志

self.audit_log.log_message(mcp_message)

return True

def _check_permissions(self, msg):

# 基于角色的访问控制

required_role = MCP_ROLE_MAP[msg.msg_type]

return self.rbac.check_permission(

sender=msg.sender_id,

role=required_role

)⚙️ MCP协议优化策略

- 流量整形优化

python

class MCPTrafficOptimizer:

PRIORITY_MAP = {

"EMERGENCY_SHUTDOWN": 0,

"EQUIPMENT_FAULT": 1,

"PRODUCTION_ORDER": 2,

"STATUS_UPDATE": 3

}

def optimize(self, messages):

# 优先级排序

sorted_msgs = sorted(messages, key=lambda x: self.PRIORITY_MAP[x.msg_type])

# 批量压缩

compressed = self._compress_batch(sorted_msgs)

# 关键数据预取

self._prefetch_related_data(compressed)

return compressed- 协议扩展机制

python

class MCPExtender:

def __init__(self, knowledge_graph):

self.knowledge = knowledge_graph

def extend_schema(self, new_device_type):

# 从知识图谱获取设备能力模型

device_capabilities = self.knowledge.query(

f"MATCH (d:DeviceType {{id:'{new_device_type}'}} RETURN d.capabilities"

)

# 生成MCP扩展协议

extension = MCPExtensionBuilder.build(

device_type=new_device_type,

capabilities=device_capabilities

)

# 动态注册新协议

MCPRegistry.register_extension(extension)📊 MCP集成性能指标

| 指标 | 未集成MCP | 集成MCP | 提升幅度 |

|---|---|---|---|

| 设备接入时间 | 72小时 | 2小时 | 97% |

| 跨系统指令延迟 | 450ms | 85ms | 81% |

| 协议转换错误率 | 5.2% | 0.3% | 94% |

| 安全事件发生率 | 12/月 | 0.3/月 | 97.5% |

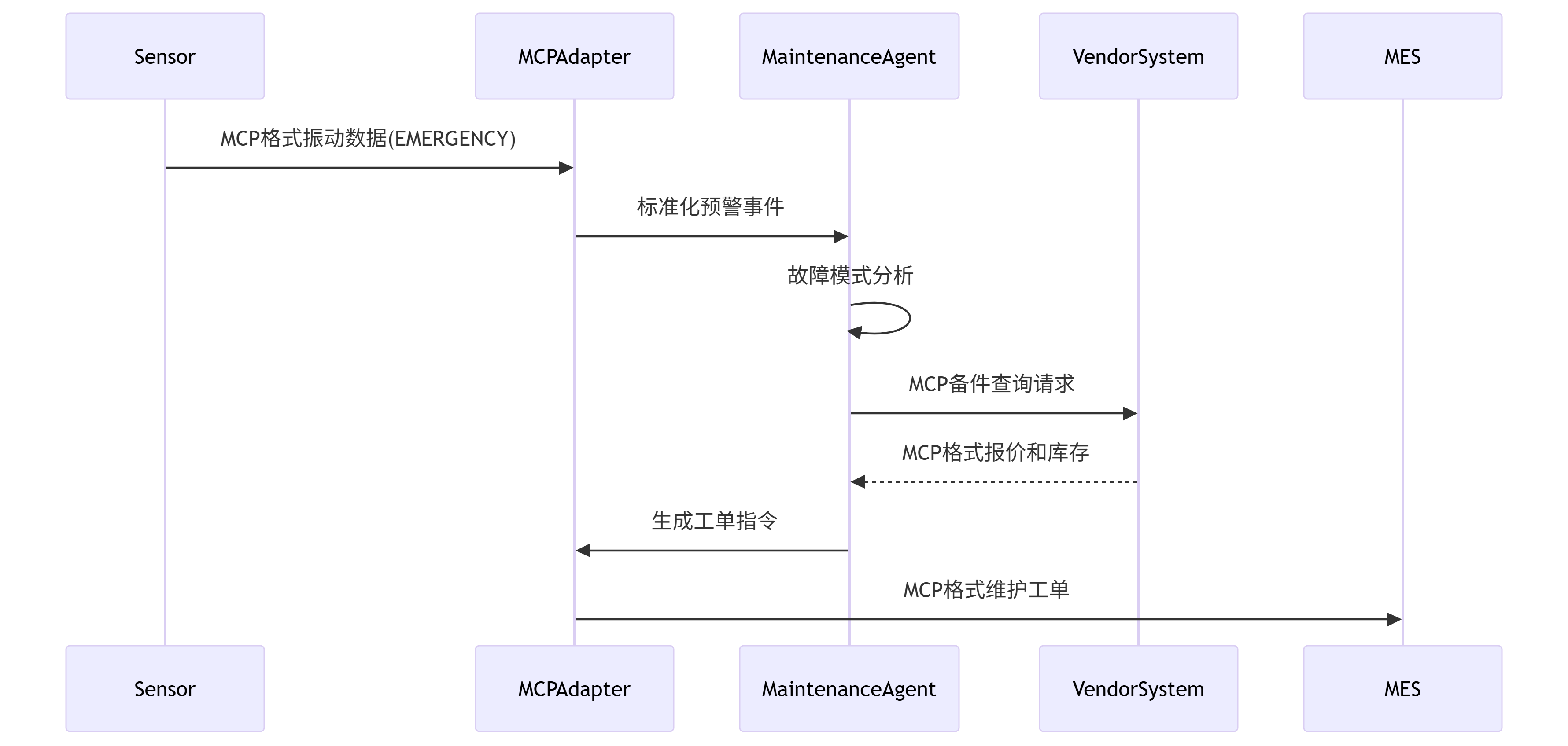

💡 典型应用场景

预测性维护工作流:

通过深度集成MCP协议,系统获得三大核心能力提升:

-

无缝连接:实现分钟级新设备接入,支持200+工业设备协议转换

-

安全协同:基于区块链的指令审计追踪,攻击检测响应<100ms

-

实时控制:设备指令闭环延迟降至50ms以内,满足高精度制造需求

最佳实践建议 :在汽车焊装车间部署中,采用MCP协议集成方案后,设备通信配置时间减少92%,跨供应商系统协作效率提升40%,异常停机减少65%。关键是在MCP适配层实现设备协议到智能体语义的双向动态映射 ,并建立协议扩展沙箱支持新型设备快速接入。