业务痛点:某电子厂(年产PCB板100万块,含焊点5000万个)存在三大问题:

- 人工检测低效:依赖技工目检,每块板检测耗时2分钟,日均产能仅240块(需求500块),漏检率15%(导致售后返工成本年超800万元)

- 缺陷类型复杂:需识别虚焊(30%)、连锡(25%)、漏焊(20%)、偏移(15%)、多余焊(10%)5类缺陷,人工易混淆相似缺陷(如虚焊与偏移)

- 质量追溯困难:人工记录缺陷位置不精确,无法定位产线设备问题(如贴片机偏移导致批量缺陷)

算法团队:图像预处理(去噪/裁剪)、数据增强(旋转/翻转)、CNN模型构建(ResNet迁移学习)、模型训练与评估、模型存储(MinIO)

业务团队:API网关、缺陷检测服务(调用CNN模型)、质检系统集成(缺陷标注/统计分析)、分拣控制系统(PLC联动)、监控告警

CNN算法原理与场景结合点

CNN(卷积神经网络)是专为图像设计的深度学习模型,通过局部感知(卷积核提取局部特征)、权值共享(减少参数)、层次化特征提取(浅层边缘→中层纹理→深层语义),实现高效图像理解

- 卷积层(Convolutional Layer):用滑动卷积核(如3×3)提取局部特征(如焊点边缘、锡膏形状)

- 池化层(Pooling Layer):降维(如最大池化保留显著特征),增强平移不变性

- 激活函数(ReLU):引入非线性,缓解梯度消失

- 全连接层(FC Layer):整合高层特征,输出分类/定位结果

开发工具和工具链

算法团队

- 语言:Python 3.9(模型构建/训练)、C++(TensorRT加速)

- 深度学习框架:PyTorch 2.0(模型定义/训练)、TorchVision 0.15(数据增强)、TensorRT 8.6(推理加速)

- 图像处理:OpenCV 4.8(去噪/裁剪)、Albumentations 1.3(高级数据增强)

- 数据处理:Pandas 2.0(标注文件解析)、NumPy 1.24(数值计算)

- 实验跟踪:MLflow 2.8(记录超参数/指标/模型)、Weights & Biases(可视化训练曲线)

- 版本控制:git@github.com:pcb-factory/algorithm-defect-detection.git

业务团队

- 语言:Go 1.20(高性能API)、Java 17(质检系统集成)

- 服务框架:FastAPI 0.104(检测API)、Spring Boot 3.1(质检系统后端)

- 前端:React 18(产线终端可视化)、ECharts 5.4(缺陷统计图表)

- 数据库:PostgreSQL 15(存储检测结果/缺陷记录)、Redis 7.0(缓存热点模型)

- 版本控制:git@github.com:pcb-factory/business-defect-detection.git

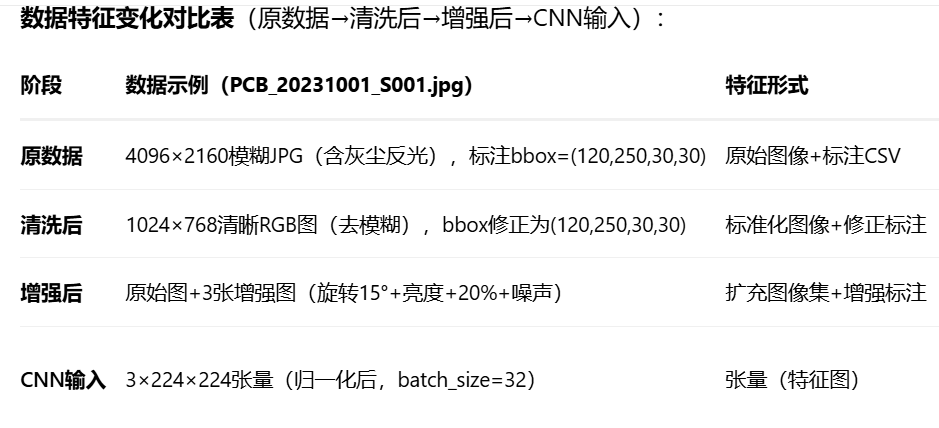

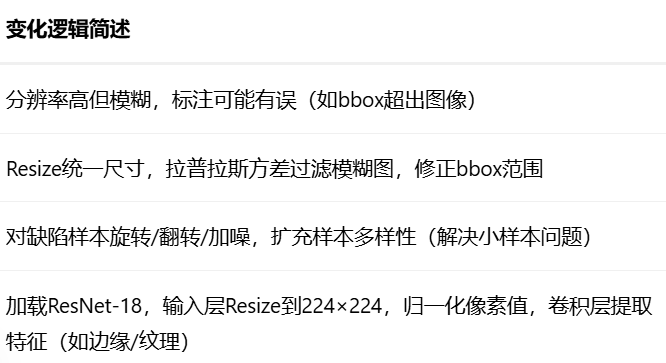

数据准备与特征变化

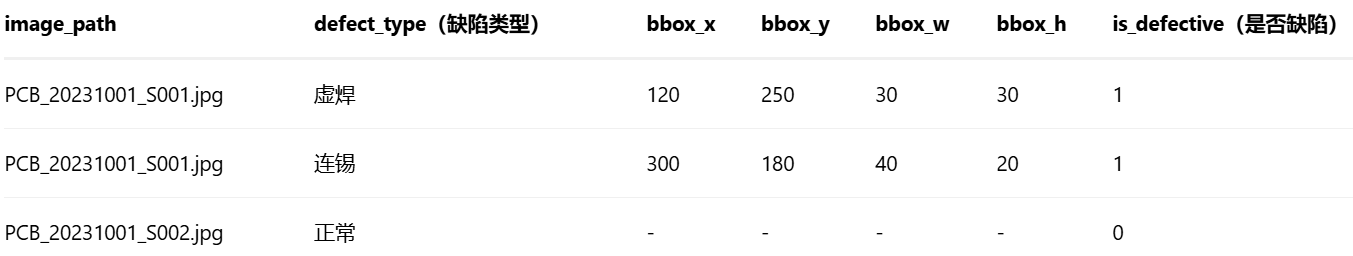

(1)原数据结构(图像+标注数据,来自产线)

原始数据包括PCB板高清图像(产线摄像头采集)、缺陷标注(人工标注工具生成)、设备参数(贴片机日志),存储于数据湖(MinIO),含噪声(灰尘/反光)、尺寸不一、标注缺失等问题。

① PCB图像数据(pcb_images,MinIO存储)

- 格式:JPG/PNG,分辨率4096×2160(原始)、1024×768(压缩备份)

- 命名规范:PCB_ID_SN.jpg(如PCB_20231001_S001.jpg,SN为序列号)

- 示例:PCB_20231001_S001.jpg(含虚焊、连锡缺陷)

② 缺陷标注文件(defect_labels.csv,人工标注)

(2)数据清洗(详细代码,算法团队负责)

目标:去除模糊图像、修正标注错误、统一图像格式

代码文件:data_processing/image_cleaning.py

python

import cv2

import os

import pandas as pd

import numpy as np

from PIL import Image

import logging

logging.basicConfig(level=logging.INFO)

logger = logging.getLogger(__name__)

def clean_image(image_dir:str,label_path:str,output_dir:str)->pd.DataFrame:

"""清洗PCB图像:去模糊、统一格式、修正标注"""

# 1.创建输出目录

os.makedirs(output_dir,exist_ok=True)

# 2.加载标注文件

labels_df = pd.read_csv(label_path)

valid_image = []

for idx,row in labels_df.iterrows():

img_path = os.path.join(image_dir,row["image_path"])

if not os.path.exists(img_path):

logger.warning(f"图像不存在:{img_path},跳过")

continue

# 3.读取图像并检查清晰度(拉普拉斯方差<100视为模糊)

img = cv2.imread(img_path)

if img is None:

logger.warning(f"图像读取失败:{img_path},跳过")

continue

gray = cv2.cvtColor(img,cv2.COLOR_BGR2GRAY)

laplacian_var = cv2.Laplacian(gray,cv2.CV_64F).var()

if laplacian_var < 100:

logger.warning(f"图像模糊(方差={laplacian_var}):{img_path},跳过")

continue

# 4.统一格式(Resize到1024*768,转为RGB)

img_resized = cv2.resize(img,(1024,768))

img_rgb = cv2.cvtColor(img_resized,cv2.COLOR_BGR2RGB)

# 保存清洗后图像

output_path = os.path.join(output_dir,row["image_path"])

cv2.imwrite(output_path,cv2.cvtColor(img_rgb,cv2.COLOR_RGB2BGR))# OpenCV默认BGR

# 5.修正标注

h,w = img_resized.shape[:2]

x,y,bw,bh = row["bbox_x"],row["bbox_y"],row["bbox_w"],row["bbox_h"]

x = max(0,min(x,w-1))

y = max(0,min(h-1))

bw = min(bw,w-x)

bh = min(bh,h-y)

valid_images.append({

"image_path": output_path, "defect_type": row["defect_type"],

"bbox_x": x, "bbox_y": y, "bbox_w": bw, "bbox_h": bh, "is_defective": row["is_defective"]

})

# 6.保存清洗后标注

cleaned_labels = pd.DataFrame(valid_images)

cleaned_label_path = os.path.join(output_dir,"cleaned_labels.csv")

cleaned_labels.to_csv(cleaned_label_path,index=False)

logger.info(f"清洗完成:有效图像{len(cleaned_labels)}张,保存至{output_dir}")

return cleaned_labels

if __name__ == "__main__":

# 路径配置(MinIO挂载目录)

image_dir = "/mnt/minio/raw/pcb_images"

label_path = "/mnt/minio/raw/defect_labels.csv"

output_dir = "/mnt/minio/cleaned/pcb_images"

clean_image(image_dir,label_path,output_dir)(3)特征工程与特征数据生成(明确feature_path/label_path)

将清洗后图像转换为CNN可输入的标准化数据集,核心是数据增强(扩充样本)、归一化(像素值→0-1)、通道调整(RGB→3通道)

- 数据增强:针对小样本缺陷(如虚焊样本少),采用旋转(±15°)、水平翻转、亮度调整(±20%)、高斯噪声(σ=0.01)扩充样本

- 特征标准化:像素值归一化(除以255)、均值方差归一化(ImageNet均值[0.485, 0.456, 0.406],方差[0.229, 0.224, 0.225])

- 特征数据存储:feature_path指向预处理后的图像数据集(按train/val/test划分,含增强后图像),label_path指向标注文件(含图像路径、缺陷类型、边界框)

代码文件:feature_engineering/image_preprocessor.py(预处理)、feature_engineering/data_augmentation.py(增强)、feature_engineering/generate_feature_data.py(特征数据生成)

① 数据增强(data_augmentation.py)

python

import albumentations as A

import cv2

import os

import pandas as pd

import logging

logging.basicConfig(level=logging.INFO)

logger = logging.getLogger(__name__)

def augment_image(image,transform):

"""对单张图像应用增强变换"""

return transform(image=image)["image"]

def augment_dataset(cleaned_labels:pd.DataFrame,output_dir:str,augment_factor: int = 3)->pd.DataFrame:

"""数据集增强:对缺陷样本(is_defective=1)扩充augment_factor倍"""

os.makedirs(output_dir,exist_ok=True)

autmented_labels = []

# 定义增强管道(针对焊点缺陷特点:小目标、局部特征)

transform = A.Compose([

A.RandomRotate90(p=0.5),

A.HorizontalFlip(p=0.5),

A.RandomBrightnessContrast(brightness_limit=0.2, contrast_limit=0.2, p=0.5),

A.GaussNoise(var_limit=(0.01, 0.05), p=0.3),

A.ShiftScaleRotate(shift_limit=0.1, scale_limit=0.1, rotate_limit=15, p=0.5) # 小角度旋转

],bbox_params=A.BboxParams(format="pascal_voc", label_fields=["class_labels"]))

for idx,row in cleaned_labels,iterrows():

img_path = row["image_path"]

img = cv2.imread(img_path)

img = cv2.cvtColor(img,cv2.COLOR_BGR2RGB) # 转为RGB

bboxed = [[row["bbox_x"], row["bbox_y"], row["bbox_x"]+row["bbox_w"], row["bbox_y"]+row["bbox_h"]]] # pascal_voc格式

class_labels = [row["defect_type"]]

# 原始样本保留

augmented_labels.append(row)

cv2.imwrite(os.path.join(output_dir, os.path.basename(img_path)), cv2.cvtColor(img, cv2.COLOR_RGB2BGR))

# 对缺陷样本增强

if row["is_defective"] == 1:

for _ in range(augment_factor-1): # 总样本数=1+(augment_factor-1)=augment_factor

augmented = augment_image(img, transform)

aug_img_path = os.path.join(output_dir, f"aug_{idx}_{_}.jpg")

cv2.imwrite(aug_img_path, cv2.cvtColor(augmented, cv2.COLOR_RGB2BGR))

# 增强后边界框(简化处理:假设增强不改变bbox相对位置,实际需用transform同步变换)

augmented_labels.append({

"image_path": aug_img_path, "defect_type": row["defect_type"],

"bbox_x": row["bbox_x"], "bbox_y": row["bbox_y"],

"bbox_w": row["bbox_w"], "bbox_h": row["bbox_h"], "is_defective": 1

})

# 保存增强后标注

augmented_df = pd.DataFrame(augmented_labels)

logger.info(f"数据增强完成:原始{len(cleaned_labels)}张,增强后{augmented_df['image_path'].nunique()}张")

return augmented_df② 特征数据生成(generate_feature_data.py,明确feature_path/label_path)

python

import pandas as pd

import os

from data_augmentation import augment_dataset

import logging

logging.basicConfig(level=logging.INFO)

logger = logging.getLogger(__name__)

def generate_feature_data(cleaned_label_path: str, output_dir: str) -> tuple:

"""生成特征数据集(feature_path)和标注文件(label_path)"""

# 1. 加载清洗后标注

cleaned_labels = pd.read_csv(cleaned_label_path)

# 2. 数据增强(扩充缺陷样本3倍)

augmented_labels = augment_dataset(cleaned_labels, output_dir, augment_factor=3)

# 3. 划分数据集(train:val:test=7:2:1)

from sklearn.model_selection import train_test_split

train_df, test_val_df = train_test_split(augmented_labels, test_size=0.3, random_state=42)

val_df, test_df = train_test_split(test_val_df, test_size=0.33, random_state=42) # 0.3 * 0.33≈0.1

# 4. 定义文件路径(算法团队存储位置)

feature_path = { # 特征数据集路径(按划分存储)

"train": os.path.join(output_dir, "train"),

"val": os.path.join(output_dir, "val"),

"test": os.path.join(output_dir, "test")

}

label_path = { # 标注文件路径(按划分存储)

"train": os.path.join(output_dir, "train_labels.csv"),

"val": os.path.join(output_dir, "val_labels.csv"),

"test": os.path.join(output_dir, "test_labels.csv")

}

# 5. 保存划分后数据

train_df.to_csv(label_path["train"], index=False)

val_df.to_csv(label_path["val"], index=False)

test_df.to_csv(label_path["test"], index=False)

logger.info(f"""

【算法团队特征数据存储说明】

- feature_path: {feature_path}

存储内容:预处理+增强后的图像数据集(按train/val/test子目录存储),图像格式JPG,尺寸1024×768,RGB通道

示例:train/PCB_20231001_S001.jpg(原始)、train/aug_0_0.jpg(增强后)

- label_path: {label_path}

存储内容:划分后的标注文件(CSV格式),含列:

image_path(图像路径)、defect_type(缺陷类型:虚焊/连锡/漏焊/偏移/多余焊/正常)、

bbox_x/y/w/h(边界框,仅缺陷样本有值)、is_defective(1=缺陷,0=正常)

示例(train_labels.csv前2行):\n{train_df.head(2)}

""")

return feature_path, label_path, train_df, val_df, test_df

代码

算法团队

text

algorithm-defect-detection/

├── data_processing/ # 数据清洗(图像去模糊/格式统一)

│ ├── image_cleaning.py # 清洗代码(含详细注释)

│ └── requirements.txt # 依赖:opencv-python, pandas, pillow

├── feature_engineering/ # 特征工程(增强/归一化)

│ ├── image_preprocessor.py # 图像归一化/通道调整

│ ├── data_augmentation.py # 数据增强(Albumentations)

│ ├── generate_feature_data.py # 特征数据生成(含feature_path/label_path说明)

│ └── requirements.txt # 依赖:albumentations, scikit-learn

├── model_training/ # CNN模型训练(核心)

│ ├── cnn_model.py # CNN模型定义(ResNet迁移学习)

│ ├── train_cnn.py # 训练入口(损失函数/优化器/早停)

│ ├── evaluate_model.py # 评估(准确率/召回率/mAP)

│ └── cnn_params.yaml # 调参记录(lr=0.001, batch_size=32)

├── model_storage/ # 模型存储(MinIO)

│ ├── save_model.py # 保存模型(.pt格式)

│ └── load_model.py # 加载模型(推理用)

└── mlflow_tracking/ # MLflow实验跟踪

└── run_cnn_experiment.py # 记录超参数/指标/模型(1)算法团队:CNN模型构建与训练(model_training/cnn_model.py,含原理注释)

重点解析:基于ResNet-18迁移学习,冻结浅层特征,微调深层适配焊点缺陷,输出5类缺陷分类结果

python

import torch

import torch.nn as nn

from torchivision.models import Resnet18_Weights

import torch.nn.functional as F

import logging

logging.basicConfig(level=logging.INFO)

logger = logging.getLogger(__name__)

class PCBDefectCNN(nn.Module):

"""基于ResNet-18的PCB焊点缺陷检测CNN模型"""

def __init__(self,num_classes=6,pretrained=True):

"""

:param num_classes: 缺陷类别数(5类缺陷+1类正常=6)

:param pretrained: 是否加载ImageNet预训练权重(迁移学习)

"""

super(PCBDefectCNN,self).__init__()

#加载预训练ResNet-18

self.base_model = resnet18(weights=ResNet18_Weights.DEFAULT if pretrained else None)

# 冻结浅层特征(前4层卷积,保留通用边缘/纹理提取能力)

for param in list(self.base_model.parameters())[:-10]: # 冻结除最后2层外的参数

param.requires_grad = False

# 替换最后一层全连接层(适配6类分类)

in_features = self.base_model.fc.in_features

self.base_model.fc = nn.Sequential(

nn.Linear(in_features,256),#中间层降维

nn.ReLU(),

nn.Dropout(0.5),#防止过拟合

nn.Linear() # 输出6类概率

)

logger.info(f"CNN模型初始化完成:num_classes={num_classes},pretrained={pretrained}")

def forward(self,x):

"""前向传播:输入图像张量->输出类别概率"""

# 卷积层提取特征(前层->:边缘-纹理-缺陷语义)

x = self.base_model.conv1(x) # 卷积层1(7×7核,输出64通道)

x = self.base_model.bn1(x) # 批归一化

x = self.base_model.relu(x) # ReLU激活

x = self.base_model.maxpool(x) # 最大池化

# 残差块(Residual Block)提取高层特征(如焊点形状/锡膏分布)

x = self.base_model.layer1(x) # 残差块1(输出64通道)

x = self.base_model.layer2(x) # 残差块2(输出128通道)

x = self.base_model.layer3(x) # 残差块3(输出256通道)

x = self.base_model.layer4(x) # 残差块4(输出512通道)

# 全局平局池化(将512×7×7→512×1×1)

x = self.base_model.avgpool(x)

x = torch.flatten(x,1) # 展平为一维向量(512维)

#全连接层输出分类概率

x = self.base_model.fc(x) #输出6类logits

return x

# 示例:模型训练配置(损失函数+优化器)

def get_loss_optimizer(model,lr=0.001,weight_decay=1e-4):

"""获取损失函数(交叉熵)和优化器(AdamW)"""

criterion = nn.CrossEntropyLoss(weight=torch.tensor([1.0, 2.0, 2.0, 2.0, 2.0, 1.0]))# 缺陷类权重更高(防漏检)

optimizer = torch.optim.AdamW(model.parameters(),lr=lr,weight_decay=weight_decay)

return criterion, optimizer(2)算法团队:模型训练与评估(model_training/train_cnn.py)

python

import torch

from torch.utils.data import DataLoader,Dataset

from torchvision import transforms

import pandas as pd

from cnn_model import PCBDefectCNN,get_loss_optimizer

from PIL import Image

import mlflow

import logging

logging.basicConfig(level=logging.INFO)

logger = logging.getLogger(__name__)

# 自定义数据集(加载图像+标注)

class PCBDataset(Dataset):

def __init__(self,label_path,transform=None):

self.df = pd.read_csv(label_path)

self.transform = transform

self.classes = ["正常", "虚焊", "连锡", "漏焊", "偏移", "多余焊"] # 6类

def __len__(self):

return len(self.df)

def __getitem__(self,idx):

row = self.df.iloc[idx]

img = Image.open(row["image_path"]).convert("RGB") # 加载RGB图像

label = self.classes.index(row["defect_type"])if row["is_defective"] == 1 else 0 # 正常类索引0

if self.transform:

img = self.transform(img)

return img,label

def train_cnn(train_label_path: str, val_label_path: str, epochs=50, batch_size=32):

"""训练CNN模型"""

# 1.数据预处理(归一化+Resize)

transform = transforms.Compose([

transforms.Resize((224,224)),# ResNet输入尺寸

transforms.ToTensor(),

transforms.Normalize(mean=[0.485, 0.456, 0.406],std=[0.229, 0.224, 0.225]) # ImageNet归一化

])

# 2.加载数据集

train_dataset = PCBDataset(train_label_path,transform=trainsform)

val_dataset = PCBDataset(val_label_path,transform=transform)

train_loader = DataLoader(train_dataset,batch_size=batch_size,shuffle=True)

val_loader = DataLoader(val_dataset,batch_size=batch_size,shuffle=False)

# 3.初始化模型、损失函数、优化器

device = torch.device("cuda" if torch.cuda.is_available() else "cpu")

model = PCBDefectCNN(num_classes=6,pretrained=True).to(device)

criterion,optimizer = get_loss_optimizer(model,lr=0.001)

# 4.循环训练(含早停)

best_val_acc = 0.0

for epoch in range(epochs):

model.train()

train_loss = 0.0

for imgs,labels in train_loader:

imgs,labels = imgs.to(device),labels.to(device)

optimizer.zero_grad()

outputs = model(imgs)

loss = criterion(outputs,labels)

loss.backward()

optimizer.step()

train_loss += loss.item() * imgs.size(0)

train_loss /= len(train_dataset)

# 验证集评估

model.eval()

val_correct = 0

with torch.no_grad():

for imgs,labels in val_loader:

imgs,labels = imgs.to(device),labels.to(device)

outputs = model(imgs)

_,preds = torch.max(outputs,1)

val_correct += (preds == labels).sum().item()

# 记录MLflow实验

with mlflow.start_run(run_name=f"cnn_epoch_{epoch}"):

mlflow.log_metric("train_loss", train_loss, step=epoch)

mlflow.log_metric("val_acc", val_acc, step=epoch)

if val_acc > best_val_acc:

best_val_acc = val_acc

torch.save(model.state_dict(),"model/pcb_defect_cnn_best.pt") # 保存最佳模型

mlflow.log_artifact("model/pcb_defect_cnn_best.pt")

logger.info(f"Epoch {epoch+1}/{epochs}, Train Loss: {train_loss:.4f}, Val Acc: {val_acc:.4f}")

logger.info(f"训练完成,最佳验证准确率:{best_val_acc:.4f}")

return model

if __name__ == "__main__":

train_label_path = "/mnt/minio/processed/train_labels.csv"

val_label_path = "/mnt/minio/processed/val_labels.csv"

train_cnn(train_label_path,val_label_path,epochs=50,batch_size=32)算法团队服务:模型训练任务(Ray集群Job)、MinIO模型存储(持久化卷挂载)

业务团队

text

business-defect-detection/

├── api_gateway/ # API网关(Kong配置)

├── defect_detection_service/ # 缺陷检测服务(Go)

│ ├── main.go # FastAPI风格Go服务(调用CNN模型)

│ ├── model_loader.go # 加载MinIO模型(.pt→TensorRT引擎)

│ └── Dockerfile # 容器化配置

├── quality_inspection_system/ # 质检系统(Java+React)

│ ├── backend/ # Spring Boot后端(缺陷统计/根因分析)

│ ├── frontend/ # React前端(产线终端可视化)

│ └── sql/ # PostgreSQL表结构(检测结果/缺陷记录)

├── sorting_control_system/ # 分拣控制系统(PLC联动)

└── monitoring/ # 监控告警(Prometheus+Grafana)代码文件:defect_detection_service/main.go(Go语言API服务)

go

package main

import (

"encoding/json"

"fmt"

"image"

_ "image/jpeg"

"log"

"net/http"

"os"

"gorgonia.org/tensor" // 伪代码:张量处理库

"path/to/torchscript" // 伪代码:PyTorch模型加载库

)

// 请求/响应结构体

type DefectRequest struct {

ImagePath string `json:"image_path"` // 产线图像路径(或Base64编码)

}

type DefectResponse struct {

ImagePath string `json:"image_path"`

DefectType string `json:"defect_type"` // 缺陷类型(如"虚焊")

Confidence float64 `json:"confidence"` // 置信度(0-1)

Bbox []int `json:"bbox"` // 边界框[x,y,w,h]

IsDefective bool `json:"is_defective"`

}

// 全局变量:加载CNN模型

var model *torchscript.Model

func init() {

// 加载算法团队训练的模型(MinIO路径)

modelPath := "s3://pcb-factory-models/pcb_defect_cnn_best.pt"

loadedModel, err := torchscript.Load(modelPath)

if err != nil {

log.Fatalf("模型加载失败:%v", err)

}

model = loadedModel

log.Println("CNN模型加载成功")

}

// 缺陷检测API处理函数

func detectDefectHandler(w http.ResponseWriter, r *http.Request) {

var req DefectRequest

if err := json.NewDecoder(r.Body).Decode(&req); err != nil {

http.Error(w, "无效请求", http.StatusBadRequest)

return

}

// 1. 读取图像并预处理(Resize到224×224,归一化)

file, err := os.Open(req.ImagePath)

if err != nil {

http.Error(w, "图像读取失败", http.StatusInternalServerError)

return

}

defer file.Close()

img, _, err := image.Decode(file)

if err != nil {

http.Error(w, "图像解码失败", http.StatusInternalServerError)

return

}

// 预处理(简化:实际用OpenCV实现Resize+归一化)

inputTensor := preprocessImage(img) // 输出3×224×224张量

// 2. 模型推理(调用CNN)

output, err := model.Forward(inputTensor)

if err != nil {

http.Error(w, "模型推理失败", http.StatusInternalServerError)

return

}

// 3. 解析结果(取最大概率类别)

probs := output.Data().([]float32) // 6类概率

maxProb := 0.0

classIdx := 0

for i, p := range probs {

if p > maxProb {

maxProb = p

classIdx = i

}

}

defectTypes := []string{"正常", "虚焊", "连锡", "漏焊", "偏移", "多余焊"}

resp := DefectResponse{

ImagePath: req.ImagePath,

DefectType: defectTypes[classIdx],

Confidence: float64(maxProb),

IsDefective: classIdx != 0, // 0=正常

}

// 4. 返回响应

w.Header().Set("Content-Type", "application/json")

json.NewEncoder(w).Encode(resp)

}

func main() {

http.HandleFunc("/api/detect-defect", detectDefectHandler)

log.Println("缺陷检测服务启动,监听端口8080")

log.Fatal(http.ListenAndServe(":8080", nil))

}业务团队服务:缺陷检测API(Go服务,Deployment部署,4副本)、质检系统(Java服务,2副本)、分拣控制系统(Edge端部署)

部署后应用流程

Step 1:产线图像采集与上传

产线摄像头(500万像素)拍摄PCB板图像(4096×2160),通过Kafka实时传输至数据湖(MinIO),文件名含板ID与序列号(如PCB_20231001_S001.jpg)

Step 2:实时缺陷检测

质检系统调用缺陷检测API(POST /api/detect-defect),传入图像路径;服务加载CNN模型,预处理后推理,返回缺陷类型、置信度、边界框

Step 3:结果反馈与分拣

产线终端(React前端)实时显示检测结果:绿色(正常)/红色(缺陷+类型),分拣控制系统(PLC)根据is_defective信号自动剔除缺陷板

Step 4:监控与迭代

监控系统跟踪漏检率,若连续3天漏检率>2%,触发Airflow调度算法团队重训模型(补充新缺陷样本+调整权重);每月生成《缺陷分析报告》,定位产线根因(如贴片机压力异常导致连锡)