目录

- [一、STM32G4 电流环闭环(二) 霍尔有感运行](#一、STM32G4 电流环闭环(二) 霍尔有感运行)

-

- [2. 霍尔有感运行](#2. 霍尔有感运行)

- 附学习参考网址

一、STM32G4 电流环闭环(二) 霍尔有感运行

2. 霍尔有感运行

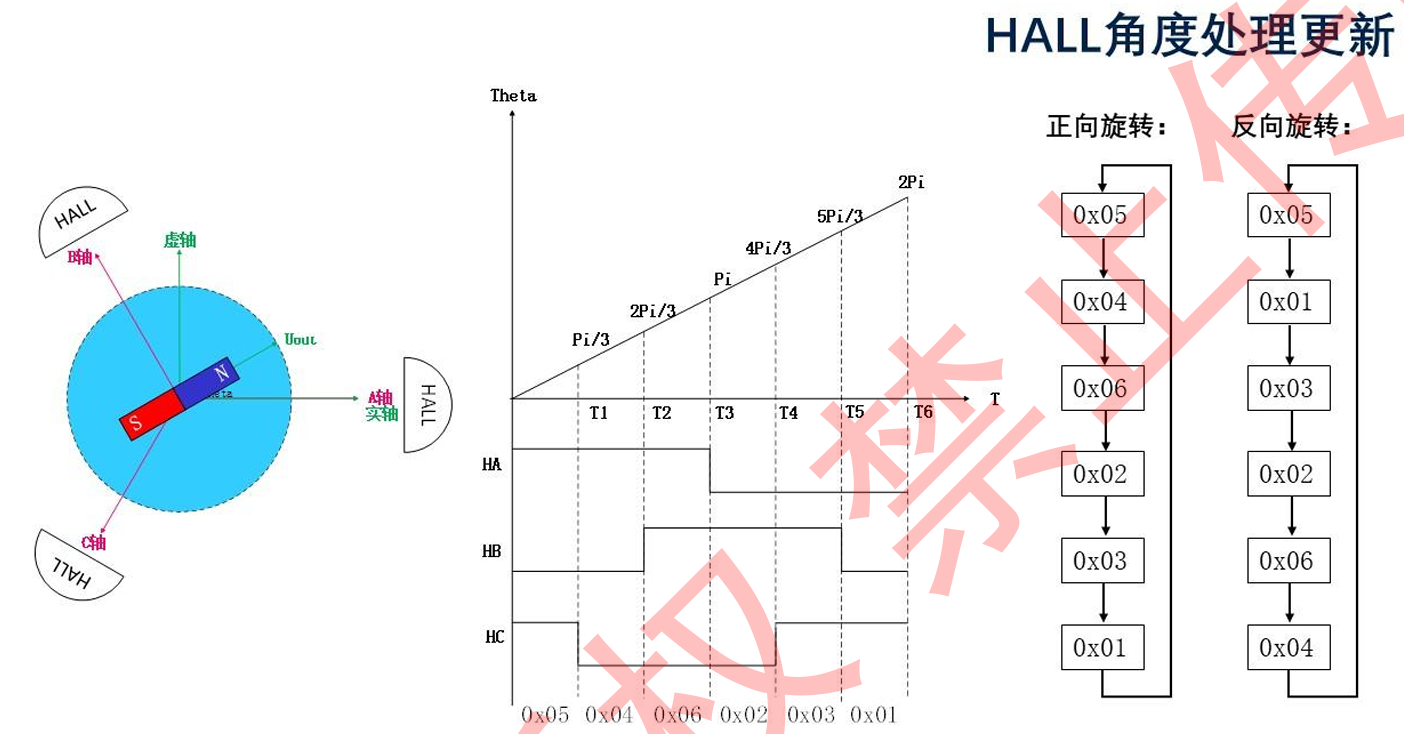

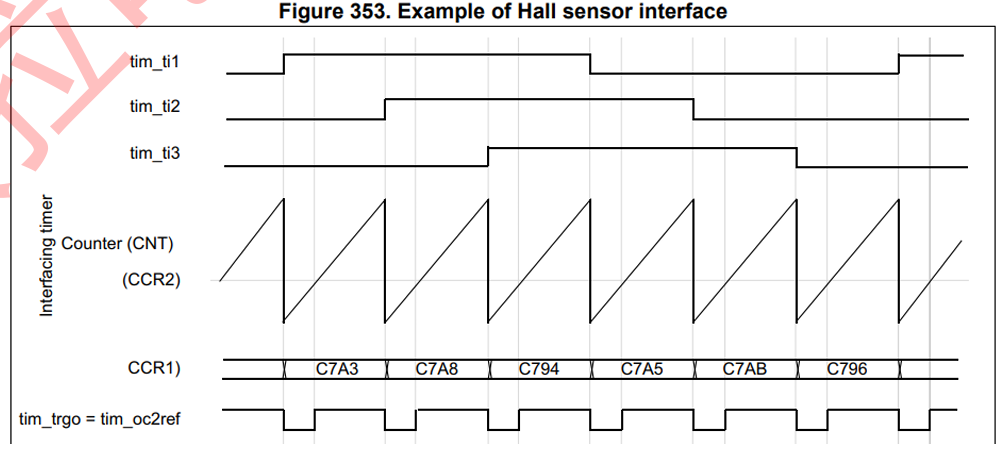

- 文章使用的BLDC在定子侧以互差120°电角度的位置安装三个霍尔元件Ha,Hb,Hc。当转子转动的时候霍尔元件会产生三个相位差120°电角度的高低电平信号。霍尔信号会将一个电周期划分为6个扇区,每个扇区60°电角度,通过单片机的定时器捕获可以获得每个扇区的运行时间t。为了获取准确的转子角度,点击绕组A相接电源正极,BC两相接电源负极,电子磁场与转子磁场共同作用,最终定位到转子零位点,也就是A相绕组的轴线位置。确定零点位置后,根据霍尔的信号顺序,可以得到霍尔信号与转子位置的对应关系,如下表所示:

-

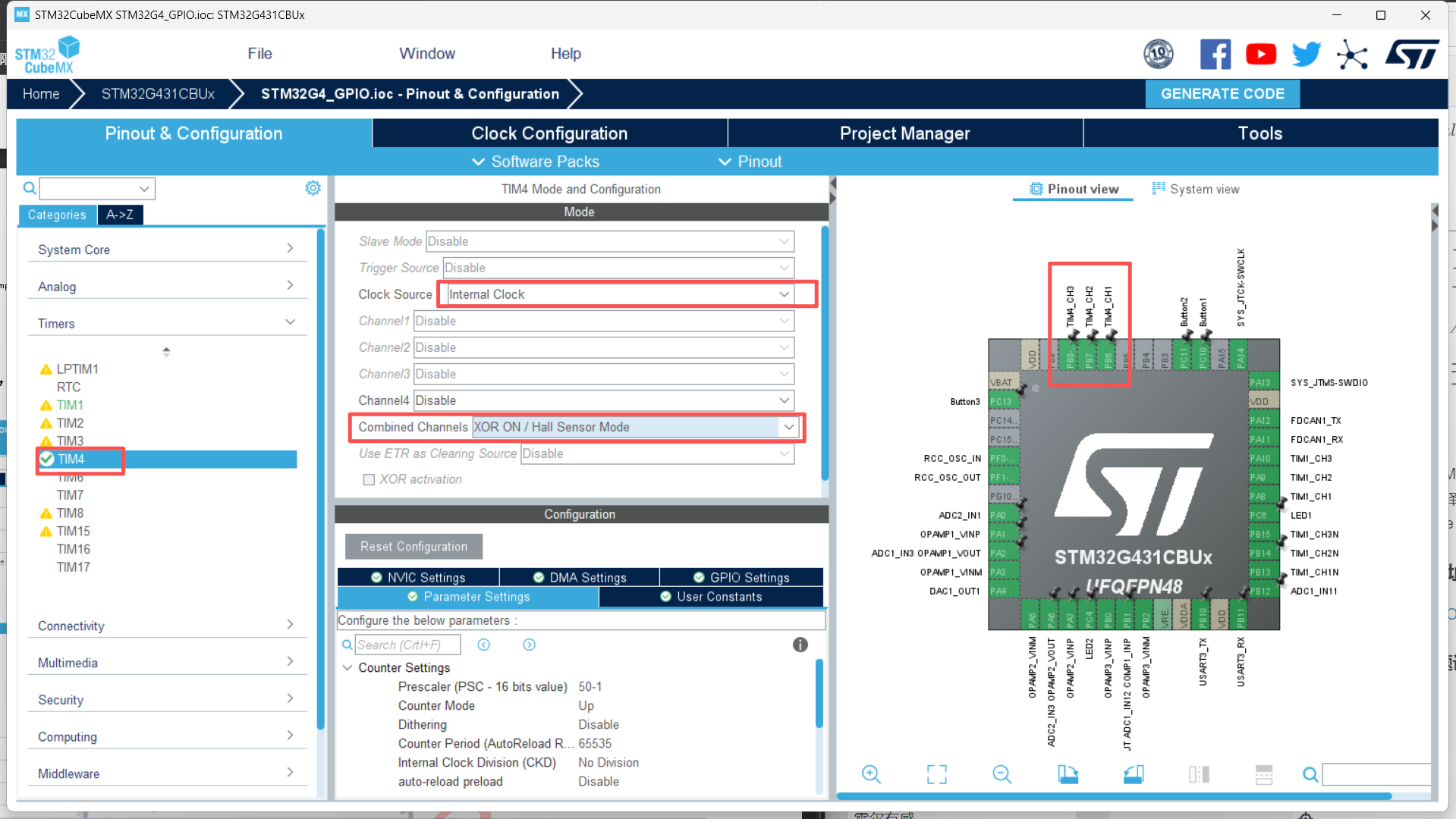

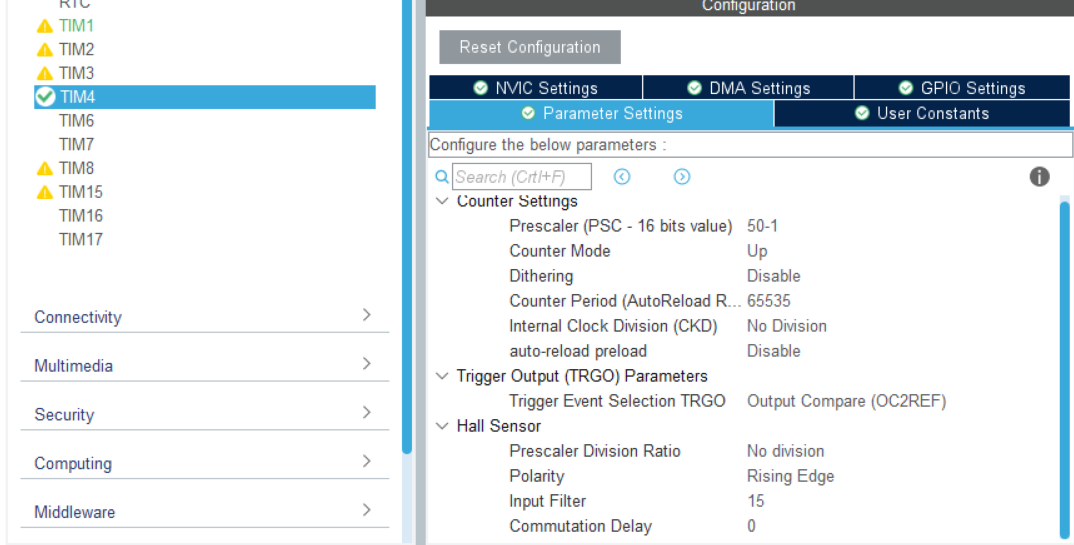

首先配置STM32G4的Hall接口;打开STM32CUBEMX;使能TIM4,选择内部时钟,在组合通道中选择XOR ON/ HALL Sensor mode;

-

配置定时器参数;16分频后,TIM4的时钟为10M;

-

生成代码并打开Keil工程

-

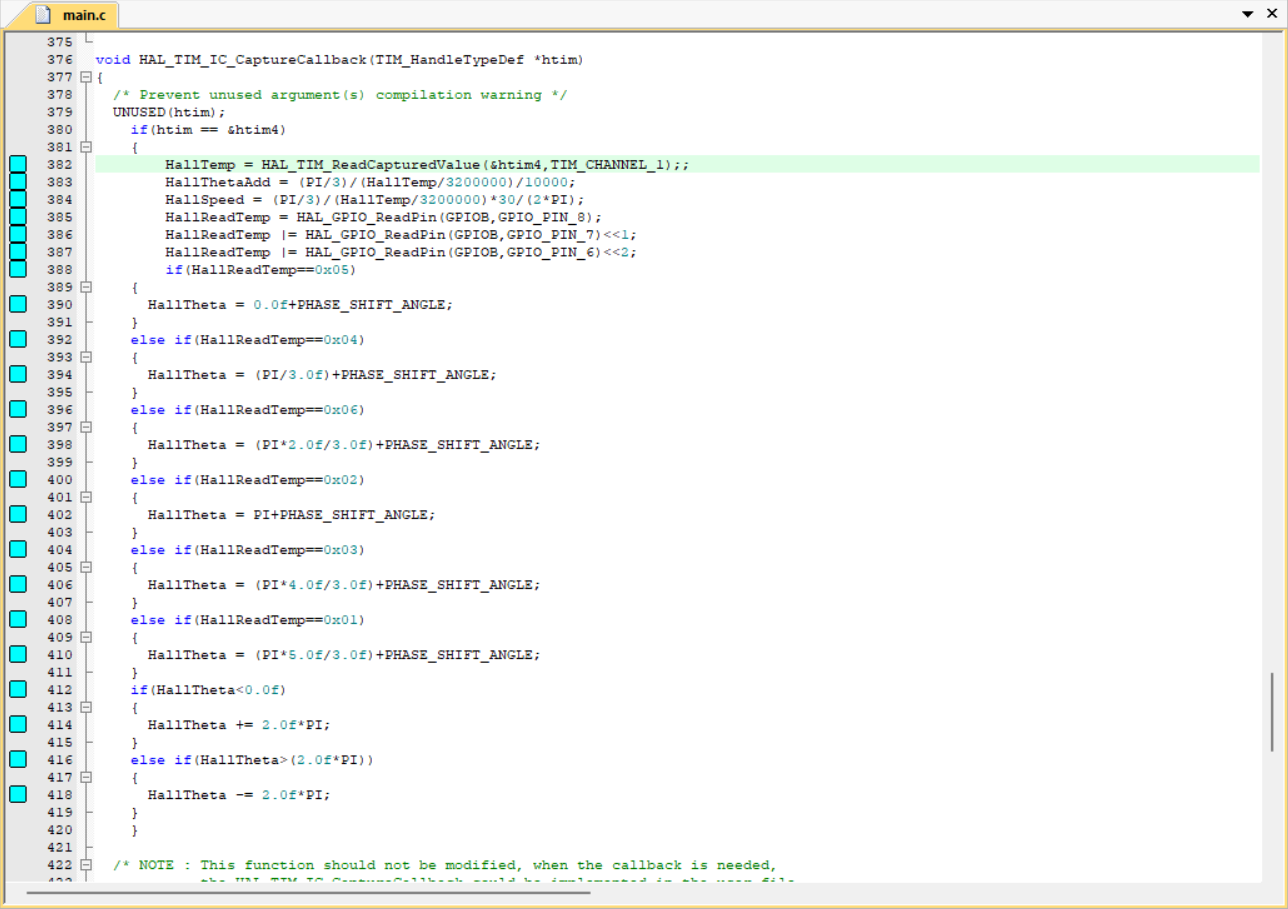

在TIM输入捕获回调函数中添加如下代码,积分时间是10k;

-

其中HALL角速度计算公式:

H a l l S p e e d = P I 3 ∗ H a l l T e m p HallSpeed = \frac{PI}{3 * HallTemp} HallSpeed=3∗HallTempPI

H a l l T h e t a = ∫ 0 H a l l T e m p H a l l S p e e d HallTheta = \int^{HallTemp}_{0}HallSpeed HallTheta=∫0HallTempHallSpeed -

在ADC注入组中断回调函数中输入,HALL传感器得到的速度和角度;在顶部添加的变量和ADC的代码修改如下

c

/* USER CODE BEGIN PV */

#define PI 3.14159265358979f

#define PHASE_SHIFT_ANGLE (float)(220.0f/360.0f*2.0f*PI)

extern DMA_HandleTypeDef hdma_usart3_tx;

uint8_t DataB1[32] = "LED1 Toggle\r\n";

uint8_t DataB2[32] = "LED2 Toggle\r\n";

uint8_t DataB3[32] = "LED1 and LED2 Open\r\n";

#define RXBUFFERSIZE 256

char RxBuffer[RXBUFFERSIZE];

uint8_t aRxBuffer;

uint8_t Uart1_Rx_Cnt = 0;

float load_data[5];

static uint8_t tempData[24] = {0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0x80,0x7F};

uint16_t DAC_temp = 0;

float Vbus,Ia,Ib,Ic;

uint8_t Motor_state = 0;

uint16_t IA_Offset,IB_Offset,IC_Offset;

uint16_t adc1_in1, adc1_in2, adc1_in3, Vpoten, adc_vbus;

uint8_t ADC_offset = 0;

FDCAN_RxHeaderTypeDef RxHeader;

FDCAN_TxHeaderTypeDef TxHeader;

uint8_t RxData[8]={NULL};

uint8_t TxData[8] = {NULL};

float HallTemp = 0;

float HallThetaAdd = 0;

float HallTheta = 0;

float HallSpeed = 0;

float HallSpeedLast = 0;

float HallSpeedtest = 0;

float alpha = 0.3;

uint8_t HallReadTemp = 0;

/* USER CODE END PV */

void HAL_ADCEx_InjectedConvCpltCallback(ADC_HandleTypeDef *hadc)

{

static uint8_t cnt;

/* Prevent unused argument(s) compilation warning */

UNUSED(hadc);

if(hadc == &hadc1)

{

if(ADC_offset == 0)

{

cnt++;

adc1_in1 = hadc1.Instance->JDR1;

adc1_in2 = hadc2.Instance->JDR1;

adc1_in3 = hadc1.Instance->JDR2;

IA_Offset += adc1_in1;

IB_Offset += adc1_in2;

IC_Offset += adc1_in3;

if(cnt >= 10)

{

ADC_offset = 1;

IA_Offset = IA_Offset/10;

IB_Offset = IB_Offset/10;

IC_Offset = IC_Offset/10;

}

}

else

{

HallTheta = HallTheta + HallThetaAdd;

if(HallTheta<0.0f)

{

HallTheta += 2.0f*PI;

}

else if(HallTheta>(2.0f*PI))

{

HallTheta -= 2.0f*PI;

}

rtU.theta = HallTheta;

rtU.SpeedFd = HallSpeed;

adc1_in1 = hadc1.Instance->JDR1;

adc1_in3 = hadc1.Instance->JDR2;

adc1_in2 = hadc2.Instance->JDR1;

Ia = (adc1_in1 - IA_Offset)*0.02197265625f;

Ib = (adc1_in2 - IB_Offset)*0.02197265625f;

Ic = (adc1_in3 - IC_Offset)*0.02197265625f;

rtU.ia = Ia;

rtU.ib = Ib;

rtU.ic = Ic;

FOC_Model_step();

TIM1->CCR1 = rtY.tABC[0];

TIM1->CCR2 = rtY.tABC[1];

TIM1->CCR3 = rtY.tABC[2];

load_data[0] = Ia;

load_data[1] = HallTemp;

load_data[2] = HallTheta;

load_data[3] = rtU.SpeedRef;

load_data[4] = HallSpeed;

memcpy(tempData, (uint8_t *)&load_data, sizeof(load_data));

HAL_UART_Transmit_DMA(&huart3,(uint8_t *)tempData,6*4);

}

}

/* NOTE : This function should not be modified. When the callback is needed,

function HAL_ADCEx_InjectedConvCpltCallback must be implemented in the user file.

*/

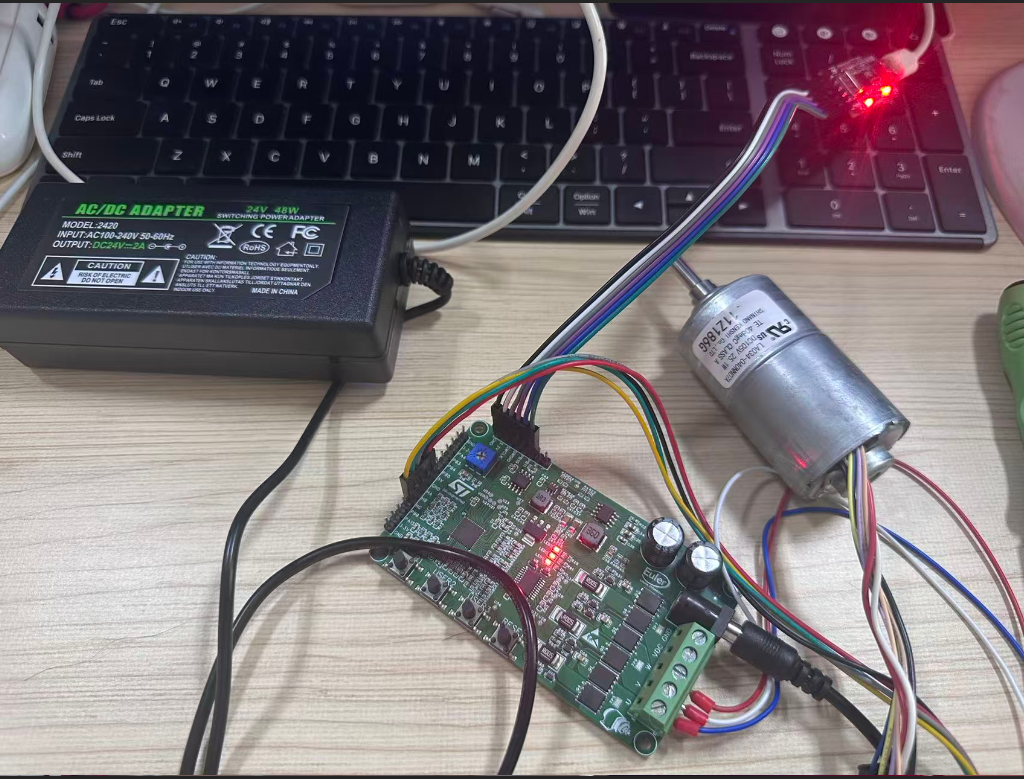

}- 编译代码,连接设备

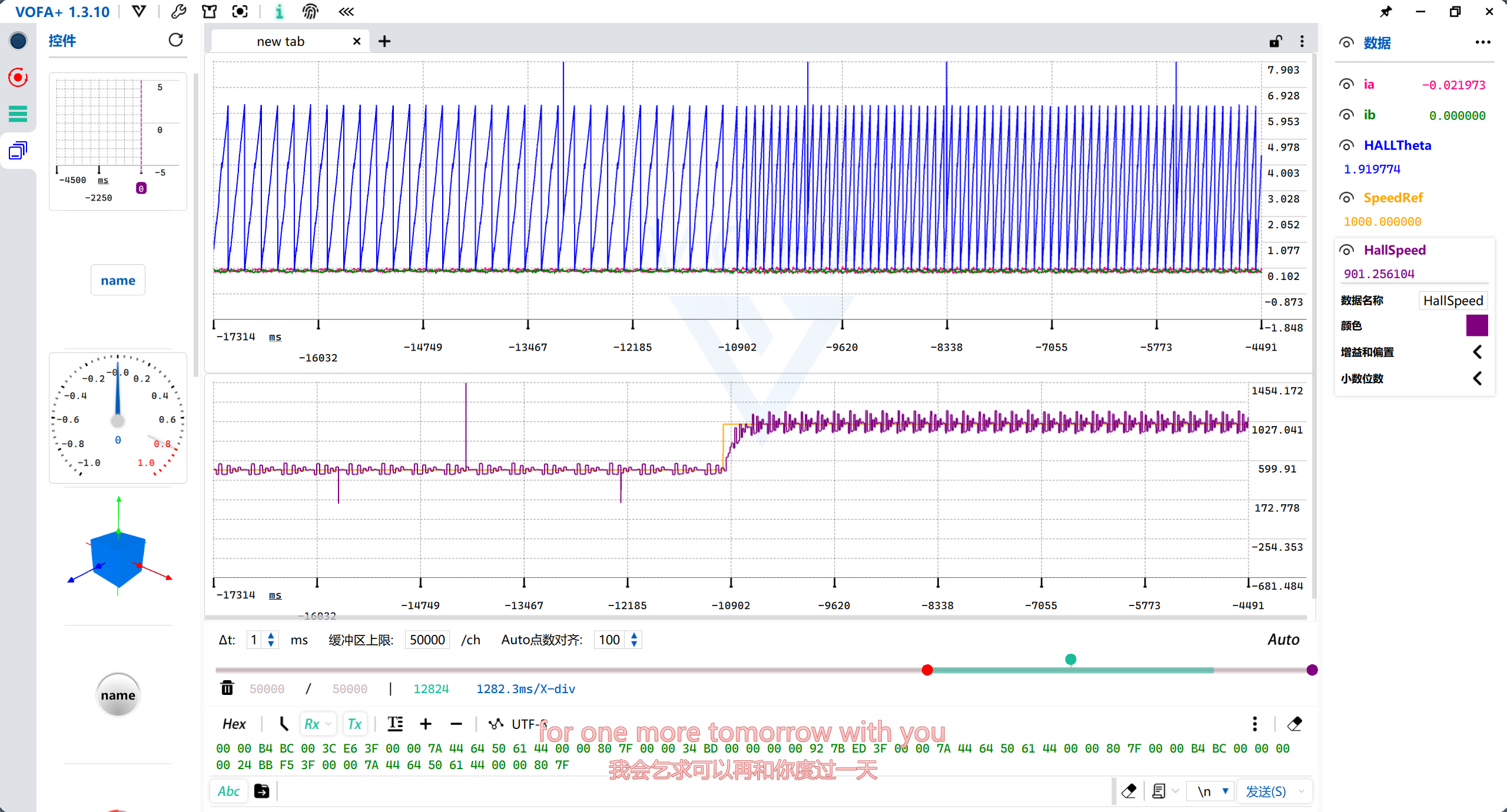

- 打开Keil的debug模式,可以试试修改速度,同时启动vofa上位机观察电流和Hall数据

- 低速的时候跟踪的不是很好